Well the Ambex experiment fell through since the thermocouples weren't K type as advertised. So I managed to get my hands on a used HotTop roaster.

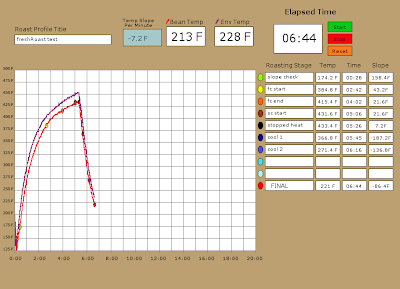

It worked the first time out. This image is from my 4th roast.

I'm not sure if it is common with HT, but I had trouble getting to the 2nd crack in a reasonable time. As you can see, it took a bit over 20 minutes to get there. I have some repairs to do on the HT, which may explain the heat problem, if there is one, due to heat loss. Regardless, I was able to get the information I needed and the profile program did its job.

1st Crack was right on schedule at 390*F, as was the 2nd Crack.

The only problem I may have is the slope is always multiples of 7.2*F. It could be the accurate slope, but I'll have to run a few different tests to see. Also, the graph sometimes seems a bit behind. The data is correct, I just think there is too much information to process for this program, Processing1.0.

Either way, if any one is reading this, enjoy.

Basically when you set the roast time on the roast, and hit start, it begins to preheat to around 300*F, drum/environment temp. The HT does have a temp reading, which read consistantly between my logged temps. I was able to submerse one TC in the beans and the 2nd higher in the drum. They were inserted through the bean drop with the lid over them, which could help explain heat loss. Regardless the temps seemed well place.

After the drum is preheated the roaster beeps and begins the countdown, this is when I dropped in the beans and started the graph. You can see the Bean Temp sank to bottom out at around 183*F. Then a steady climb to finally hitting first crack at 17min.

Next roast I'll try a smaller batch to test. This particular roast was set at 20 minutes with 250 grams of coffee.